Water Resources

As a steward of one of our most important resources, El Paso Water is committed to meeting the community's present and future water demands. For over a century, El Paso has relied on both river water and groundwater for municipal water supply and now proudly supplies 97 percent of all municipal water in El Paso County.

Sources:

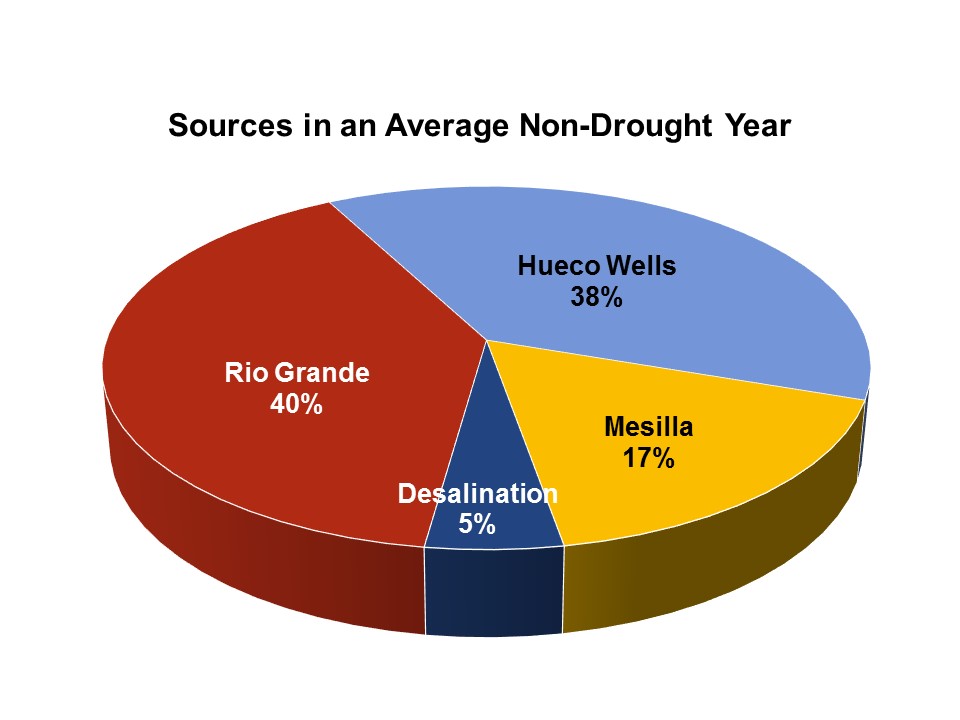

- River water is supplied from the Rio Grande and makes up nearly half of El Paso’s potable water supply. The Rio Grande flows that are diverted in the El Paso area are primarily derived from snowmelt runoff in southern Colorado and northern New Mexico. Learn more about the Rio Grande and the Elephant Butte Reservoir here.

- Groundwater supplies are pumped from the Mesilla and Hueco bolsons, which are shown in the figure below. These groundwater basins lie under parts of New Mexico, Texas and Chihuahua, Mexico. Learn more about our aquifers here.

- Over the years, we have also added desalinated water to meet peak summer demand and water needs when river supplies are limited. Learn more about our desalination process here.

Management

EPWater's pumping in the Hueco Bolson peaked at about 26 billion gallons per year in 1989. Due to concerns regarding long-term sustainability (e.g. Muller and Price, 1979 and Boyle Engineering, 1991), EPWater implemented the following strategies:

- Adopted a rate structure that increases the cost of water for high use

- Promoted water conservation through various incentive programs

- Increased the use of Rio Grande water

- Expanded the reuse of reclaimed water

Over nearly 30 years, El Paso has reduced water consumption by 35% thanks to an aggressive conservation program and ordinance adopted in 1991. EPWater’s population has since grown by 130,000 people, yet the utility is producing less water than at that time. Every gallon saved is a gallon for our future.

EPWater is also planning 50 years into the future to ensure a sustainable water supply that meets El Paso’s future water demands. Diversification of water supplies will prove essential to this plan with added resources to include Advanced Water Purification, Aquifer Recharge and Importation.